VRM vs Ball Mill for Cement Grinding Page 1 of 1

Feb 10, 2016· re VRM vs Ball Mill for Cement Grinding. Specific power consumption high for ball mill and Low for VRM ; Maintenance costs high for VRM and low for Ball mill

WhatsApp)

WhatsApp)

Feb 10, 2016· re VRM vs Ball Mill for Cement Grinding. Specific power consumption high for ball mill and Low for VRM ; Maintenance costs high for VRM and low for Ball mill

Cement Plant Maintenance | LinkedIn. 27 Jun 2011 ... I currently have a challenge on a cement grinding ball mill, initially one of the junction bolts gave in and my ...

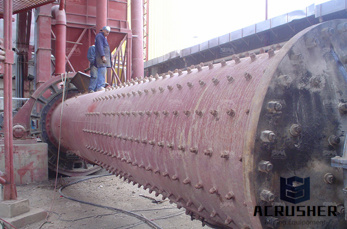

Maintenance of the cement Grinding mill. Cement Grinding mill is professional cement grinding equipment. When the cement ball mill works, it needs very big grinding ...

Ball Mill Maintenance Inside a Cement Factory from XSM. Shanghai XSM (Ball Mill Maintenance Inside a Cement Factory) is professional .

MAINTENENCE IN CEMENT INDUSTRY PROJECT ... The importance of Maintenance in Cement Industries The importance of ... Ball mill liner thickness measurement every ...

Know More ... Installation and maintenance of cement ball mill , Mainly introduces the cement ball mill cement ball mill installation commissioning and maintenance...

Putting a Ball or SAG Mill on Care and Maintenance. ... SAG or Large Ball Mill in care and maintenance does not have to be ... a concrete "shelf" on the ...

03 CEMENT MILLS Twochamber ball mills for the cement industry are available in different designs. The bearings can be either trunnion bearings or

Ball Mill Routine Maintenance. Ball mill is really a device most often used in our production, however in actual production, Ball mill will frequently be a number of ...

Cement Ball Mill Maintenance, Wholesale Various High Quality Cement Ball Mill Maintenance Products from Global Cement Ball Mill Maintenance Suppliers and Cement Ball ...

Improvements in Cement Ficem. clinker 90 130 kWh / t cement in a modern plant, more for older o For ball mills, only 3 6% of absorbed energy is ...

FL ball mill for cement grinding. Versatile system based on standard modules 2 ... maintenance. The size distribution of the grinding media in the coarse

Cement mill Wikipedia, the free encyclopedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder ...

MAINTENANCE OF BALL MILLS. ... Ball mill maintenance and repair – IdeaMarketersThe Free ... Cement ball mills, Operation and ...

ball mill maintenance in cement factory. ball mill maintenance in a cement factory . SAM is a professional manufacturer and exporter of mining equipment, such as ...

The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals.

cement ball mill maintenance pdf – Grinding Mill China. maintenance slide shoe bearing cement mill Overview of maintenance slide shoe bearing cement mill Ball Mill ...

Cement Ball Mill Maintenance Pdf. Inquiry. Industry News. Background and introduction representing the UK . 1 Novel cements: low energy, low carbon cements ...

Ball Mill Maintenance Content: fine maintenance, mainly inspect the oil amount, adjust the gap between different parts, firm the bolt, replace the impact plate or ...

GEARS DRIVE TECHNOLOGY I Ball mill maintenance by Dr Devinder S Grewal, PE, Cement plant operators often have to make decisions about repair or

FL ball mill for cement grinding. ... oct ball mill maintenance manual on mill installation and .for the larger mills with trunnion bearings provided with ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... maintenance discussion and ... ball mill operation has been established throughout the history of ball mill cement ...

Grinding trends in the cement industry Cement . Worldwide, there are around 600 separate grinding plants in the cement industry. These receive their feed ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

WhatsApp)

WhatsApp)